PROTECTION.SYSTEMS

DESIGN FOR

SUSTAINMENT

Form Cut Australia, based in Southern Australia, is an integrated design-led manufacturer with a strong focus on creating purposeful solutions together for our large Australian and International client base.

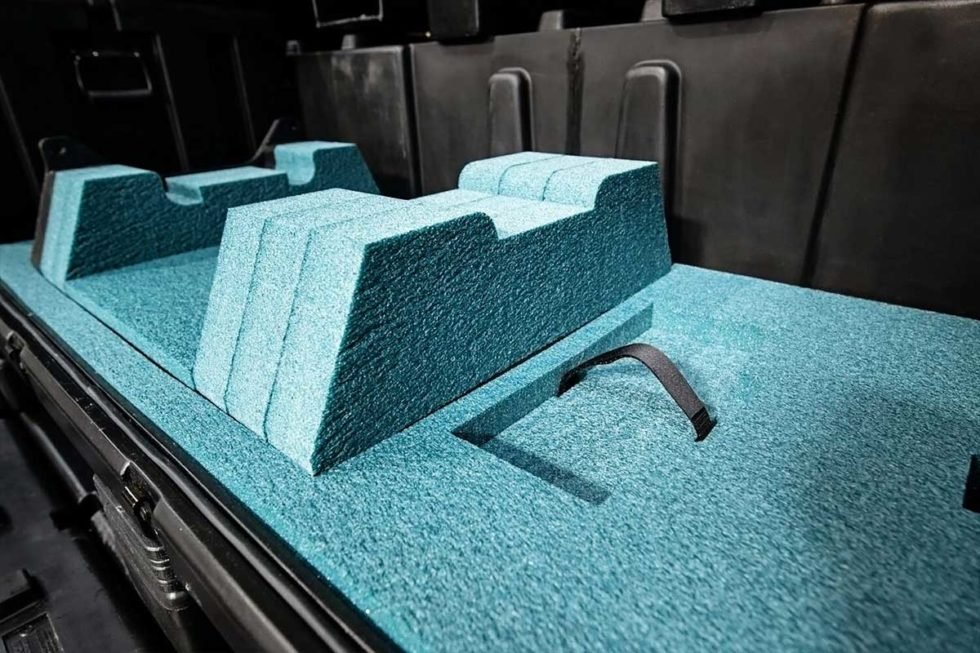

Our specialist team of Industrial Designers and Engineers deliver custom, protective packaging solutions for military use, incorporating shock and vibration attenuation for fragile and sensitive products, thermal and acoustic insulation and linings, seals, gaskets, sub-assemblies, occupant protection systems and a growing range of our own product lines.

Established in 1999, Form Cut Australia has grown from strength to strength, starting life as a die cutting operation, building on experience, introducing new processes, services and products.

Located within the TONSLEY Innovation Precinct, South Australia, 15 minutes south of Adelaide, Form Cut supplies products nationwide and internationally. Applying a philosophy of continuous improvement and technological development we are proud to announce that we have been certified through SAI Global to the ISO 9001:2015 Quality Management System.

SUPPORTING

GLOBAL SUPPLY CHAINS

Our clients include:

Today, a core section of our business is directed towards the manufacture of innovative protection solutions. While Form Cut Australia is active in multiple industries across the Australian manufacturing sector, it is a particularly strong contributor in the defence sector. Protecting Defence Lives and Assets Form Cut is actively involved in the manufacture of protective transit packaging solutions compliant to the Defence Packaging Standard, DEF(AUST) 1000C and the development and manufacture of Occupant Protection Systems currently integrated into the ADF’s Protected Mobility Vehicle (PMV) Bushmaster fleet.

Supported by Form Cut’s established design and development processes which incorporate important criteria such as product fragility, sensitivity, presentation, material, recyclability and end use application, we have recently established DMI our Damage Minimisation Initiative. DMI operates independantly to Form Cut, applying a structure process of Enquiry, Qualification, Analysis, Concept, Detailing, Prototyping and Production.

DMI, Damage Minimisation Initiative, is Form Cut Australia’s analysis process, applied across a client’s supply chain, ensuring capture of the complete Through Life requirements for asset protection. Form Cut Australia’s approach significantly reduces the cost of ownership, across the life of type.

Employing state of the art in-house CAD and CNC technologies we continue to enhance our profiling, die cutting and varied proprietary fabrication techniques. Relevant to our work in Defence industry, Form Cut Australia has extensive experience designing and manufacturing products in the following categories:

Presentation Cases

Packing frames

Packing Sets

Tote Packaging

Cartons & Containers

Custom Inserts

Protective Packaging

Floatation Systems

Dunnage

Reusable Packaging

Industrial Seals

Shielding